Comprehensive Guide to Industrial Process Control Software Solutions

Understanding Industrial Process Control Software

Industrial process control software is a vital component in the modern manufacturing and production landscape. It facilitates the automation, monitoring, and optimization of industrial processes, resulting in enhanced efficiency and productivity. These software solutions are designed to handle complex processes by providing real-time data analysis, control algorithms, and system interfaces.

Key Features of Process Control Software

The primary features of industrial process control software include data acquisition, real-time monitoring, and process automation. By capturing data from various sensors and devices, the software provides operators with a comprehensive view of the production environment. Real-time monitoring allows for immediate response to any anomalies, while process automation minimizes human intervention, reducing the risk of errors.

Another significant feature is the integration capabilities of the software. Seamless integration with existing systems and machinery ensures that all components work in harmony, enhancing operational efficiency. Additionally, these systems often offer advanced analytics tools that help in predictive maintenance and process optimization.

Types of Process Control Software

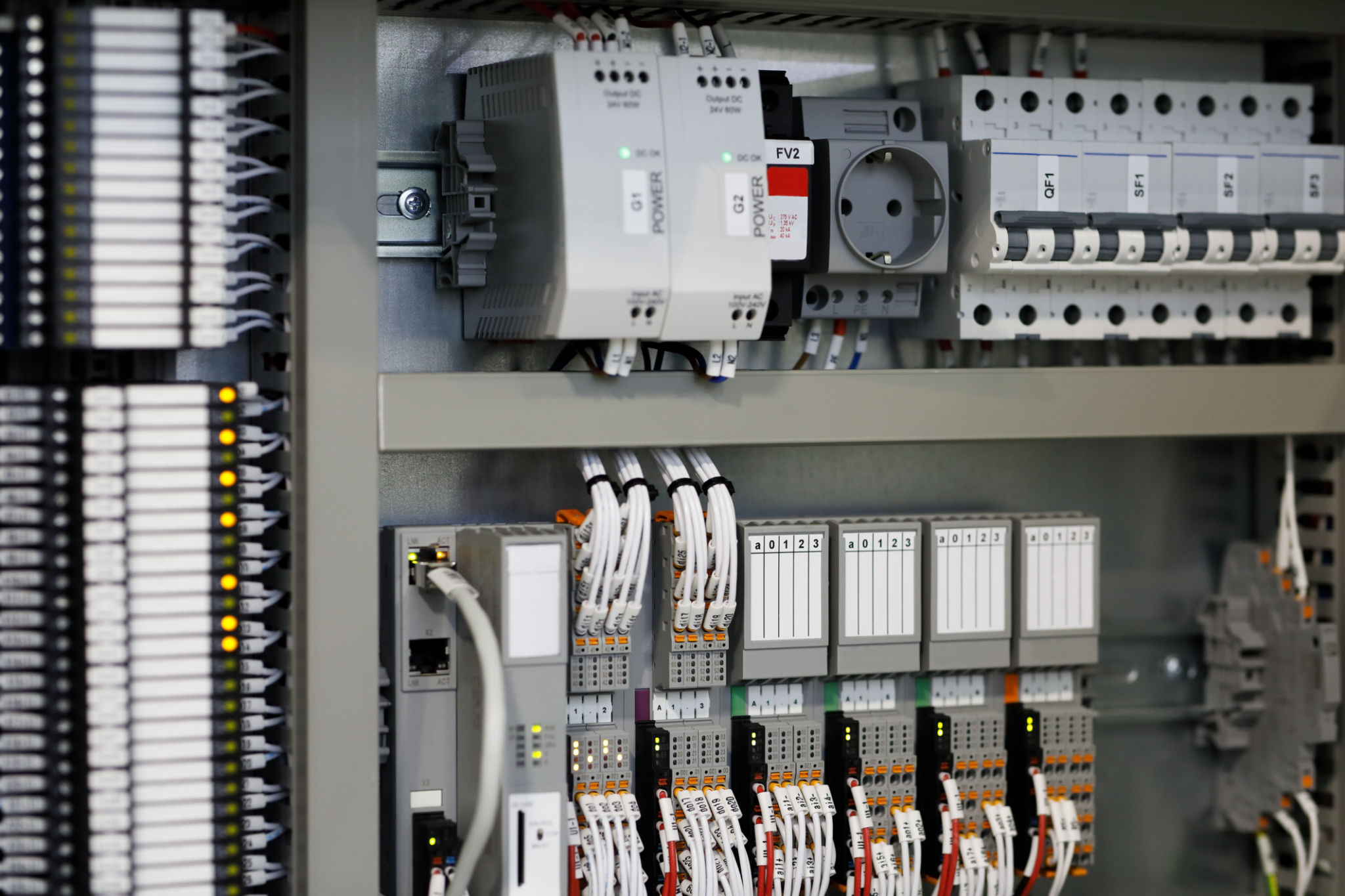

There are several types of industrial process control software available, each tailored to specific needs. Some common types include Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), and Supervisory Control and Data Acquisition (SCADA) systems. DCS is ideal for large-scale processes where centralized control is necessary. PLCs are versatile and can handle discrete processes, while SCADA systems are excellent for long-distance data transmission and monitoring.

Benefits of Implementing Process Control Solutions

Implementing industrial process control software comes with numerous benefits. One of the most significant advantages is improved **operational efficiency**. By automating repetitive tasks and enabling real-time adjustments, companies can reduce downtime and increase throughput. Another benefit is enhanced **safety**. With continuous monitoring, potential hazards can be detected early, preventing accidents and ensuring worker safety.

Moreover, these solutions offer **cost savings**. By optimizing resource use and reducing waste, companies can lower operational costs significantly. Additionally, advanced analytics facilitate better **decision-making**, allowing managers to make informed choices that align with business objectives.

Challenges in Deploying Process Control Software

Despite the advantages, deploying industrial process control software can present several challenges. One common issue is the **integration with legacy systems**. Many industrial environments operate with outdated technology that may not easily integrate with modern solutions. This requires careful planning and possibly upgrading existing infrastructure.

Another challenge is the **cost of implementation**. While the long-term savings are significant, the initial investment can be substantial, particularly for small to medium-sized enterprises. Training staff to operate new systems effectively can also pose a challenge, necessitating comprehensive training programs.

Choosing the Right Software for Your Needs

Selecting the right industrial process control software depends on various factors, including the specific needs of your industry, the complexity of your processes, and budget constraints. It's essential to conduct a thorough assessment of your current systems and identify areas where improvements are needed.

Consider engaging with solution providers to understand their offerings better. Many companies offer demonstrations or trials that allow you to test the software's capabilities before making a significant investment. Additionally, consulting with experts or peers in your industry can provide valuable insights into what solutions have worked well for others.

The Future of Industrial Process Control

The future of industrial process control software is promising, with advancements in technology paving the way for more innovative solutions. **Artificial intelligence** and machine learning are becoming integral components, offering predictive capabilities that further enhance efficiency and reduce downtime.

Moreover, the rise of the **Internet of Things (IoT)** in industrial settings is transforming how data is collected and analyzed. IoT devices can provide even more granular data, leading to better insights and more precise control over processes.

Conclusion

Industrial process control software solutions are crucial for businesses looking to optimize their operations and remain competitive in a rapidly evolving market. By understanding the features, benefits, and challenges associated with these solutions, companies can make informed decisions that align with their strategic goals. As technology continues to advance, embracing these innovations will be key to maintaining efficiency and productivity in industrial environments.