The Benefits of Implementing Automation Solutions in Manufacturing

Introduction

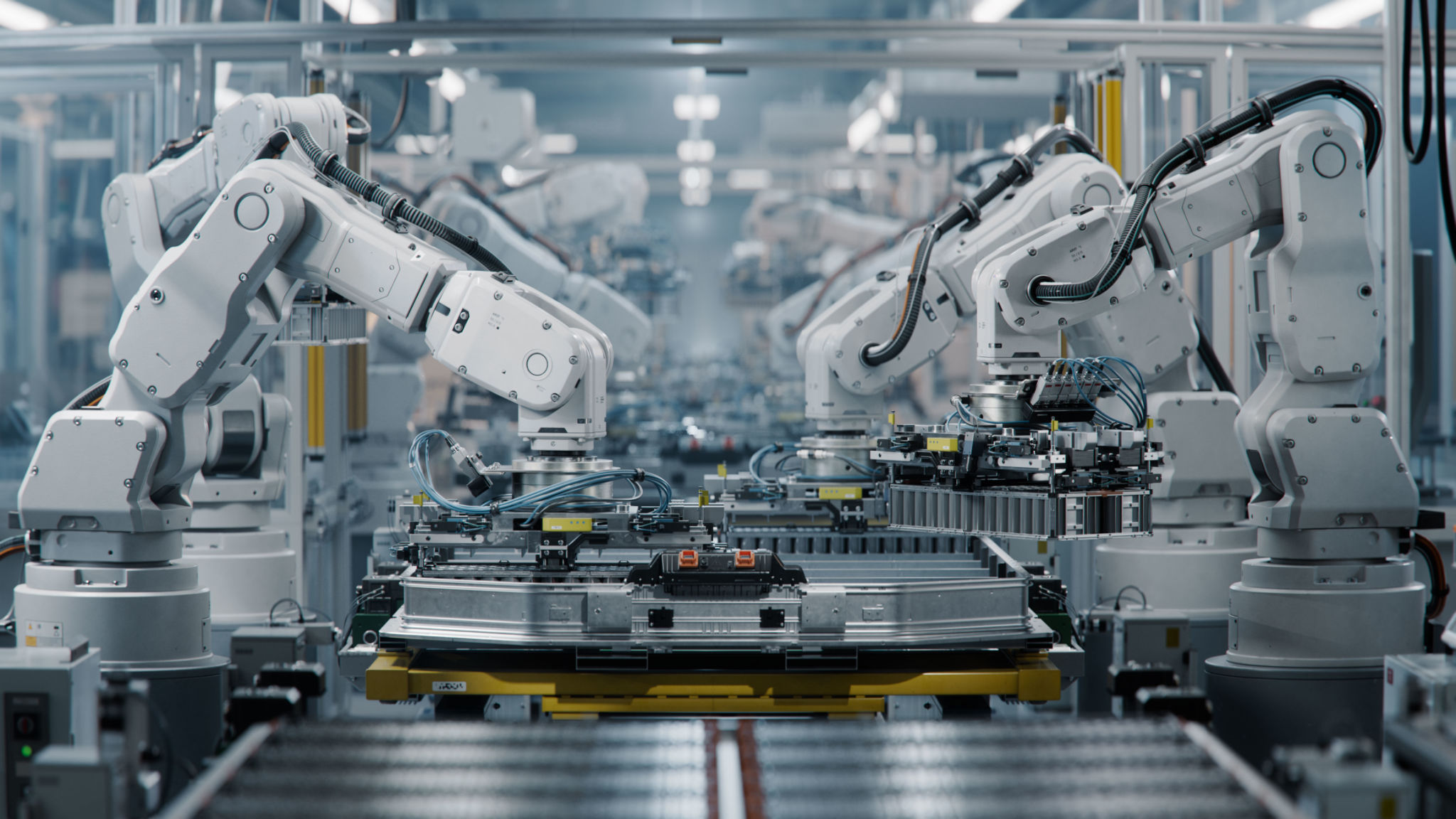

In the rapidly evolving landscape of manufacturing, businesses are continually seeking ways to enhance efficiency, reduce costs, and maintain high standards of quality. One of the most effective strategies to achieve these goals is through the implementation of automation solutions. Automation technologies not only streamline processes but also provide a significant competitive edge. In this blog post, we will explore the various benefits of adopting automation in manufacturing.

Enhanced Productivity

One of the primary benefits of implementing automation in manufacturing is the substantial boost in productivity. Automated systems can operate continuously without the need for breaks, thereby increasing output levels significantly. By minimizing manual intervention, manufacturers can achieve higher production rates while maintaining consistent quality.

Reduction in Human Error

Human error is an inevitable factor in manual operations, often leading to production delays and increased waste. Automation mitigates this issue by ensuring precision and consistency in repetitive tasks. With automated systems, manufacturers can significantly reduce the occurrence of errors, leading to improved product quality and customer satisfaction.

Cost Savings

Although the initial investment in automation technology may seem substantial, the long-term cost savings are undeniable. Automation reduces labor costs by minimizing the need for manual labor in repetitive and monotonous tasks. Additionally, automated systems often result in lower scrap rates and reduced energy consumption, further contributing to cost efficiency.

Improved Safety

Manufacturing environments can pose various safety risks to workers, particularly when dealing with hazardous materials or complex machinery. Automation helps to alleviate these risks by reducing human involvement in dangerous tasks. By using robotic systems and automated processes, manufacturers can create a safer workplace, protecting their workforce and reducing the likelihood of accidents.

Scalability and Flexibility

Automation solutions offer unparalleled scalability and flexibility. Manufacturers can quickly adapt to market changes or increased demand by scaling operations up or down as needed. Automated systems can be reprogrammed or reconfigured to accommodate new products or processes without significant downtime.

Data-Driven Insights

Modern automation solutions are equipped with advanced data analytics capabilities. These systems gather and analyze data in real-time, providing valuable insights into production processes and operational efficiency. By leveraging this data, manufacturers can make informed decisions, optimize production lines, and identify areas for improvement.

Conclusion

The implementation of automation solutions in manufacturing offers a multitude of benefits that extend beyond mere productivity gains. From cost savings and enhanced safety to improved product quality and data-driven insights, automation is a key driver of success in the modern manufacturing industry. As technology continues to evolve, embracing automation will become increasingly vital for manufacturers seeking to remain competitive in a global market.